I didn't make my normal trek to Arlington, Texas, for work on Tuesday morning. Instead, I ventured across town to the city of Allen to spend some quality time witnessing the finer points of trading card production. I left, however, with two huge regrets: One, that I couldn't stay longer -- like, say, two weeks longer; and two, that it took me 15 years in this industry to finally make it to the production facility.

I didn’t make my normal trek to Panini America headquarters in Arlington, Texas, for work on Tuesday morning. Instead, I ventured across town to the city of Allen to spend some quality time witnessing the finer points of trading card production.

I left, however, with two huge regrets: One, that I couldn’t stay longer — like, say, two weeks longer; and two, that it took me 15 years in this industry to finally make it to the production facility.

What in the world took me so long?

It truly was a remarkable experience that left me buzzing, beaming and wide-eyed with wonderment — sometimes all at once. From start to finish, I was completely mesmerized.

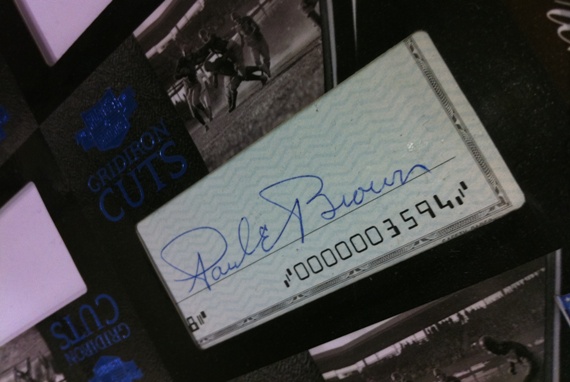

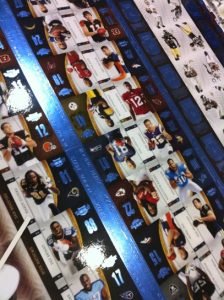

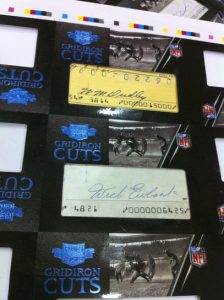

I got to see it all, from how the cards begin as 100-up sheets and how those sheets get passed through a slitter to become cards. I got to see how those cards then travel on conveyor belts before being fed into packs via predetermined “loops.” I got to see how those packs are sealed and then placed into boxes and how those boxes are shrink-wrapped and then placed into cases.

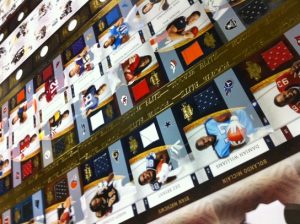

I got to see the application of UV coating, card backs being serial numbered, die-cut cards being die cut and the construction of memorabilia cards.

The good news: You’ll get to see it all, too, beginning Friday with the first of several videos chronicling my four-hour fantasy field trip. I’m certain you’ll find the sights and sounds to be as utterly fascinating as I did.

But until tomorrow’s premiere, I figured this gallery of still shots from my visit would help set the table.

Enjoy . . .

These photos remind me of the time when Mr. Rogers would play a video of how things are made on his show. I guess the best thing I can really say in regards to these photos is that, while I enjoy seeing the product in my hand, it’s even more rewarding seeing the process of how they end up in my hand. Seeing how the patches are applied to the card and then seeing the magenta print runs is really cool. Here’s a question though. I noticed they are uncut sheets when they are printed. What happens if you run them through another color and, for some reason, the sheet is off and the prints are ruined (an unlikely scenario, but things happen). Do you have to go through and pull out all the swatches and re-apply them to another sheet? Anyways, enough rambling. I cannot wait for these products to hit shelves. They look great, and I look forward to the day when I open a pack of cards and unfold a whole jersey! HAHA!

Good question, Simeon. I’ll have to ask around and find out about that. Glad to hear stuff like this only enhances your enjoyment of the product. That’s precisely why we do it. Thanks for the feedback and be sure to check out the first video when it launches tomorrow afternoon.

If the print is bad then it wouldn’t have been attached to the swatch sheets.

They are done in layers, front – center – back, and then glued together.

Simeon, how’s this for fantastic customer service: Loops above is one of Panini’s fabulous graphic designers. In addition, Carlos Torrez, Panini America’s Football Brand manager, wanted me to post the following information:

What you are viewing is the Magenta (Red) printing plate for 2010 Panini Plates & Patches Football rom the base commons (100 cards).

Here’s the breakdown:

Black printing plate (players will have one of these versions):

• Plate only

• Plate with prime jersey swatch

• Plate with prime jersey swatch and auto

• Plate with auto

Cyan (Blue) printing plate (players will have one of these versions):

• Plate only

• Plate with prime jersey swatch

• Plate with prime jersey swatch and auto

• Plate with auto

Magenta (Red) printing plate (players will have one of these versions):

• Plate only

• Plate with prime jersey swatch

• Plate with Prime jersey swatch and auto

• Plate with auto

Yellow printing plate (players will have one of these versions):

• Plate only

• Plate with prime jersey swatch

• Plate with prime jersey swatch and auto

• Plate with auto

In addition, here is the breakdown for the rookies in the set:

100 Rookies plates

Black – Plate with auto

Cyan – Plate with auto

Magenta – Plate with auto

Yellow – Plate with auto

35 RPS Rookie Plates

Black – Plate with prime jersey swatch and auto

Cyan – Plate with Prime jersey swatch and auto

Magenta – Plate with prime jersey swatch and auto

Yellow – Plate with prime jersey swatch and auto

This is great. Those patch sheets are awesome.

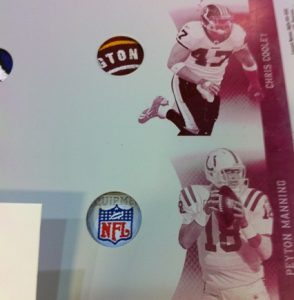

In the picture below, on the top left, are those 2-player cards with one guy upside down? If so, awesome!

http://paniniamerica.files.wordpress.com/2010/12/packout15.jpg?w=544

Also, those Hillis swatch cards are gonna be HOT. Browns fans finally have somebody they like more than the overrated Cribbs.

Very interesting pictures. It is cool to see how the cards are manufactured. One favor though, can you put some descriptions with the pictures to give us a better idea of what we are looking at? Some of the pictures are pretty self explanatory, but some could use some describing… Thanks!